Understanding The Role of Simulation Modeling

Raid Al-Aomar, Edward J.Williams and Onur M. Ülgen.

Understanding The Role of Simulation Modeling

After understanding the concepts and aspects of the term “simulation modeling,” it is necessary to clarify the role that simulation plays in developing production and business systems. Initially, consider the use of simulation technically and economically and then present the spectrum of simulation modeling applications in manufacturing and service sectors.

Simulation Justified

“Why and when to simulate?” and “How can we justify a simulation project?” are key questions that often cross the mind of simulation practitioners, engineers, and decision-makers. We turn to simulation because of simulation’s capabilities that are unique and powerful in system representation and performance estimation under real-world conditions. Most real-world processes in production and business systems are complex, stochastic, and highly nonlinear and dynamic. Other modeling types such as graphical, mathematical, and physical models fall short in providing a cost-effective and usable system representation under such conditions.

“Decision support” is another common justification of simulation studies. Obviously, engineers and managers want to make the best decisions possible, especially when encountering critical stages of design, expansion, or improvement projects. Simulation studies may reveal insurmountable problems and save cost, effort, and time. They reduce the cost of wrong capital commitments, reduce investments risk, increase design efficiency, and improve the overall system performance.

Although simulation studies might be costly and time-consuming in some cases, the benefits and savings obtained from such studies often recover the simulation cost and avoid much larger costs. Simulation costs are typically the initial simulation software and computer cost, yearly maintenance and upgrade cost, training cost, engineering time cost, and other costs for traveling, preparing presentations with multimedia tools, and so on. Such costs are often recovered through the long-term savings from increasing productivity and efficiency.

Simulation Applications

A better answer to the question “why simulate?” can be reached by exploring the wide spectrum of simulation applications to various aspects of business, science, and technology. This spectrum starts by designing queuing systems and extends to designing communication networks, production systems, and business operations. Simulation models of manufacturing systems can be used for many objectives including:

- Determining throughput capability of a manufacturing cell, an assembly line, or a production system.

- Configuring labor resources in an intensive assembly process.

- Determining the needed number of automated guided vehicles (AGVs) in a complex material handling system (MHS).

- Determining the size and resources in a complex automated storage and retrieval system (AS/RS).

- Determining best ordering policies for an inventory control system.

- Validating the outcomes of material requirement planning (MRP).

- Determining buffer sizes for work-in-progress (WIP) in an assembly line.

For business operations, simulation models can be also used for a wide range of applications including:

- Determining the number of bank tellers that results in reducing customers waiting time by a certain percentage.

- Designing distribution and transportation networks to improve the performance of logistic and supply chains.

- Analyzing the financial portfolio of a company over time.

- Designing the operating policies in a fast food restaurant to reduce customer Time-In-System and increase customer satisfaction.

- Evaluating hardware and software requirements for a computer network.

- Scheduling the working pattern of the medical staff in an emergency room (ER) to reduce patients’ waiting time.

- Testing the feasibility of different product development processes and evaluating their impact on the company’s budget and strategy.

- Designing communication systems and data transfer protocols.

- Designing traffic control systems.

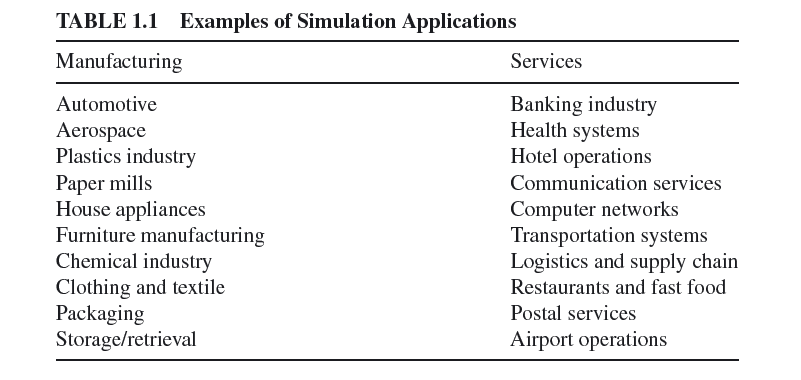

Table 1.1 below shows a summary of ten examples of simulation applications in both manufacturing and service sectors.

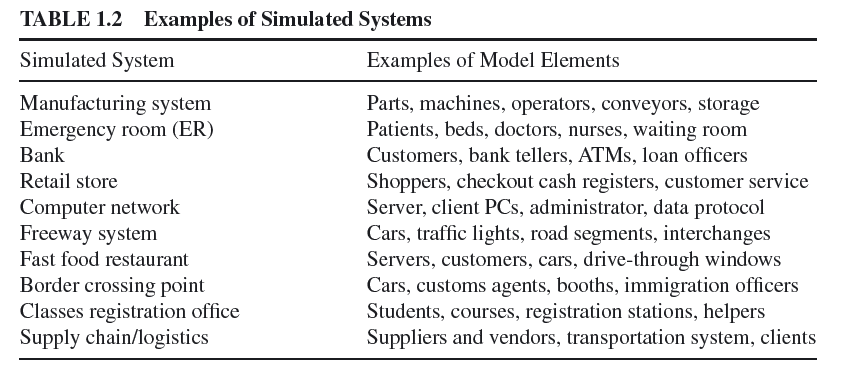

To reach the goals of the simulation study, certain elements of each simulated system often become the focus of the simulation model. Modeling and tracking such elements provide attributes and statistics necessary to design, improve, and optimize the underlying system performance. Table 1.2 shows a summary of ten examples of simulated systems with examples of principal model elements.

Simulation Precautions

Like any other engineering tool, simulation has limitations. Such limitations should be realized by practitioners and should not discourage analysts and decision-makers from using simulation. Knowing the limitations of simulation should emphasize using it wisely and should motivate the user to develop creative methods and establish the correct assumptions in order to benefit from the powerful simulation capabilities. Still, however, certain precautions should be considered to avoid the potential pitfalls of simulation studies. We should pay attention to the following issues when considering simulation:

- The simulation analyst as well as the decision-maker should be able to answer the question “when not to simulate?” Simulation studies may not be used for solving problems of relative simplicity. Such problems can be solved using engineering analysis, common sense, or mathematical models.

- The cost and time of simulation should be considered and planned well. Many simulation studies are underestimated in terms of time and cost. Some decision-makers think of simulation as model building although it consumes less time and cost when compared to data collection and output analysis.

- The skill and knowledge of the simulation analyst need to be addressed. Essential skills for simulation practitioners include systems thinking, fluency in programming and simulation software, knowledge in statistics, strong communication and analytical skills, project management (PM) skills, ability to work in teams, and creativity in design and problem-solving.

- Expectations from the simulation study should be realistic and not exaggerated. A lot of professionals think of simulation as a “crystal ball” through which they can predict and optimize system behavior. It should be clear that simulation models by themselves are not system optimizers. They are flexible experimental platforms that facilitate planning, what-if analysis, statistical analyses, experimental design, and optimization.

- The time frame of the simulation project needs to be realistic and properly set. Insufficient time and resources at various project stages, improper work breakdown structure, and lack of project control are issues that result in project delays and low-quality deliverables. Typical PM skills are essential to execute the simulation project in an efficient manner.

- The results obtained from simulation models are as good as the model data inputs, assumptions, and logical design. The commonly used phrase of “garbage-in-garbage-out (GIGO)” is very much applicable to simulation studies. Hence, special attention should be paid to data inputs selection, filtering, and simulation assumptions.

- The analyst should pay attention to the level of detail incorporated into the model. Some study objectives can be reached with macro-level modeling while some others require micro-level modeling. The analyst should decide on the proper level of model detail and avoid details that are irrelevant to simulation objectives.

- Model verification and validation is not a trivial task. As will be discussed later, model verification aims at making sure that the model behaves according to intended model logic. Model validation, on the other hand, focuses on making sure that the model behaves as the actual system. Both practices determine the degree of model reliability and usefulness.

- The results of simulation can be easily misinterpreted. Hence, the analyst should concentrate the effort on collecting reliable results from the model through proper settings of run controls and by using the proper statistical analyses. Typical mistakes in interpreting simulation results include relying on short run time, including biases caused by model initial conditions in the results, using the results of only one simulation replication, and relying on the mean of the response while ignoring variability inherent in response.

- The analyst should pay attention to communicating simulation inputs and outputs clearly and correctly to all parties of the simulation study. Also, the results of the simulation model should be communicated to get feedback from parties on relevancy and accuracy of the results.

- The analyst should avoid using wrong measures of performance when building and analyzing the model results. Such measures should represent the kind of information required for the analyst and the decision-maker to draw conclusions and inferences on model behavior.

- The analyst should also avoid the misuse of model animation. In fact, animation is an important simulation capability that provides engineers and decision-makers with a valuable tool of system visualization. Such capability is also useful for model debugging, verification, and validation. However, some may misuse model animation by relying solely on observing the model for short-term, which may not necessarily reflect its long-term behavior.

- Finally, the analyst should select the appropriate simulation software tool that is capable of modeling the underlying system and providing the required simulation results. Criteria for selecting the proper simulation software tool typically include price, modeling capabilities, learning curve, animation, produced reports, input modeling, output analysis, and add-in modules. Simulation packages vary in their capabilities and inclusiveness of different modeling systems and techniques such MHS, human modeling, statistical tools, animation.

APPLICATIONS OF SIMULATION MODELING*

The following list includes examples of discrete-event simulation (DES) applications for a variety of facilities or processes that are typical in multiple industries such as manufacturing, banking, IT, supply chain, healthcare, transportation, fast food restaurants, airports, entertainment, government, and military.

- A manufacturing plant with machines, people, transport devices, conveyor belts, and storage place.

- A bank or other personal-service operation, with different kinds of customers, servers, and facilities like teller windows, automated teller machines (ATMs), loan desks, and safety deposit boxes.

- An IT organization with software products, developers (e.g., coders, testers, reviewers, etc), file servers, automated testing tools, software migrations and releases.

- A distribution network of plants, warehouses, and transportation links.

- An emergency facility in a hospital, including personnel, rooms, equipment, supplies, and patient transport.

- A field service operation for appliances or office equipment, with potential customers scattered across a geographic area, service technicians with different qualifications, trucks with different parts and tools, and a central depot and dispatch center.

- A computer network with servers, clients, disk drives, tape drives, printer, networking capabilities, and operators.

- Freeway system or road segments, interchanges, controls, and traffic.

- A central insurance claims office where a lot of paperwork is received, reviewed, copied, filed, and mailed by people and machines.

- A chemical products plant with storage tanks, pipelines, reactor vessels, and railway tanker cars in which to ship the finished product.

- A fast-food restaurant with workers of different types, customers, equipment, and supplies.

- A supermarket with inventory control, checkout, and customer service.

- A theme park with rides, stores, restaurants, workers, guests, and parking lots.

- Pedestrian flow in malls, museums, buildings, stadiums, airports, plants, etc.

- Military planes, rockets, etc. that can be operational at any one time under different scenarios, maintenance, material handling, and supply chain operations.

This content featured is an excerpt from Process Simulation Using WITNESS®, First Edition. Raid Al-Aomar, Edward J.Williams and Onur M. Ülgen.

© 2015 John Wiley & Sons, Inc. Published 2015 by John Wiley & Sons, Inc.

*Ref.: Kelton, W.D., R.P. Sadowski, and D.A. Sadowski, Simulation with Arena, WCB/McGraw-Hill, Boston, MA, 1998 and Ulgen, O.M. 2021

Let our experts show you how our Services can support your projects!

Recent posts