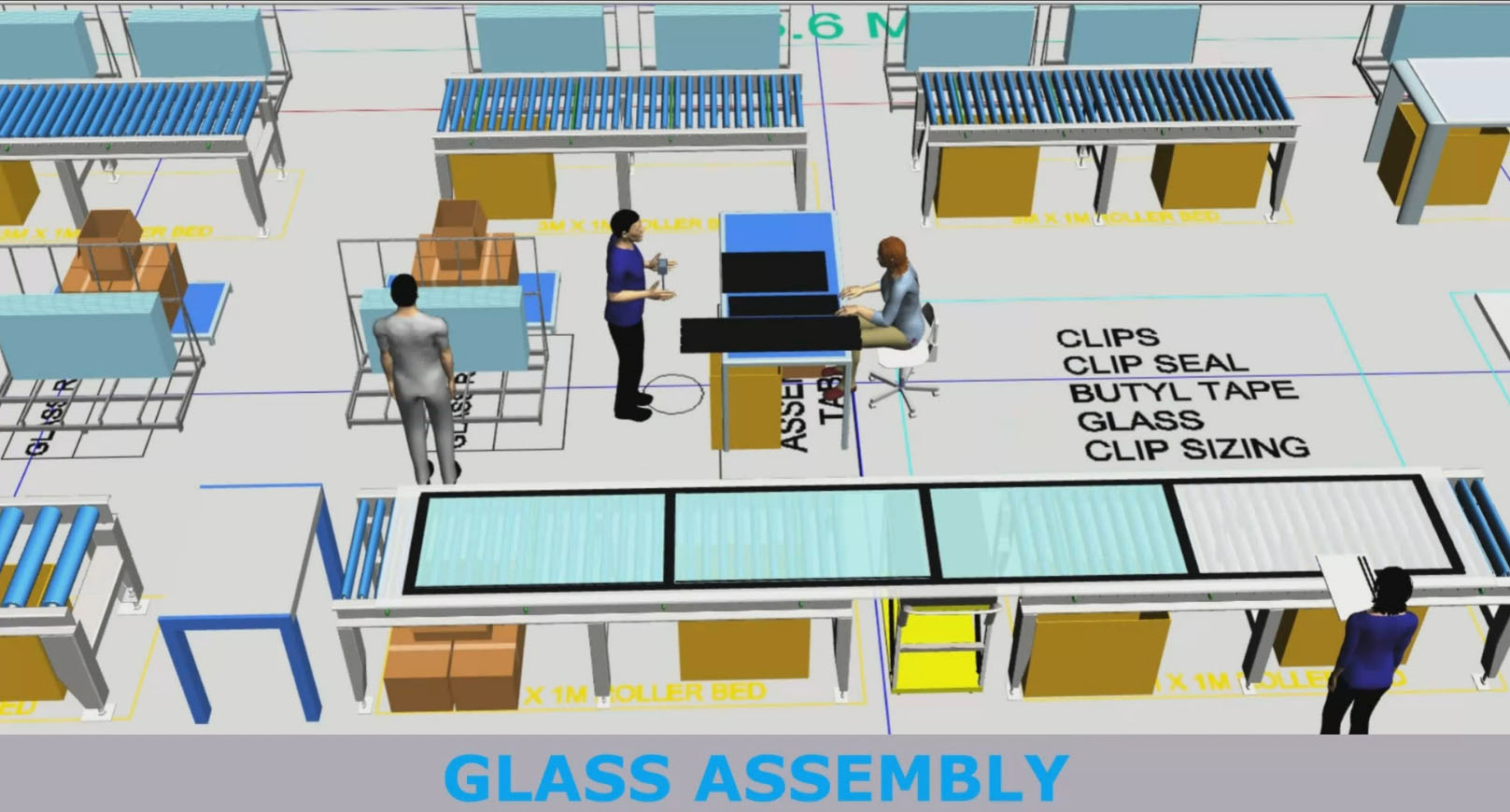

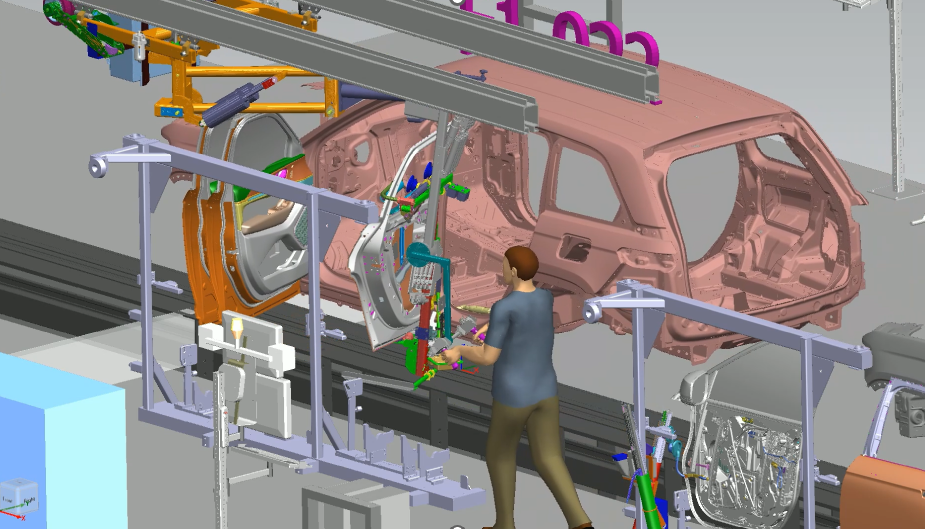

PMC’s Factory Layout and Design Optimization services cut costs, boost throughput, and maximize space efficiency. Let our 40+ years of experience improve your OLE (Overall Labor Efficiency).

Request a Quote

Factory layout design optimizes manufacturing processes by strategically arranging equipment to meet specific goals, enhancing safety, profitability, and flexibility.

PMC has experience in:

PMC specializes in industrial engineering, leveraging decades of experience to optimize layouts. Our approach incorporates advanced tools like Static Material Flow Analysis and dynamic simulations for thorough evaluation and effective solutions, enhancing workflow efficiency and operational productivity.

PMC optimized our layout and really improved our production line. They helped us cut down on downtime and learn to work more efficiently.

Simulation helped us learn how to maximize capacity and get more done in less time. It's been a game-changer for us.

PMC made a big difference in our warehouse operations. We now work smarter and get things done more efficiently." – Mike M., Warehouse Operations Director, Warehouse Logistics

Factory layout design optimizes manufacturing processes by strategically arranging equipment to meet specific goals, enhancing safety, profitability, and flexibility.

PMC has experience in:

Send a message to our team by filing out the form below. Describe your project, ask questions, or even request a bid.

An expert from our team will be in touch with you within one business day!