Improve Efficiency and Precision in Manufacturing with Custom Jigs and Fixtures

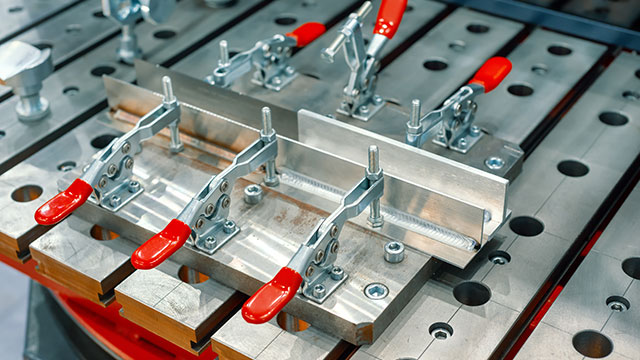

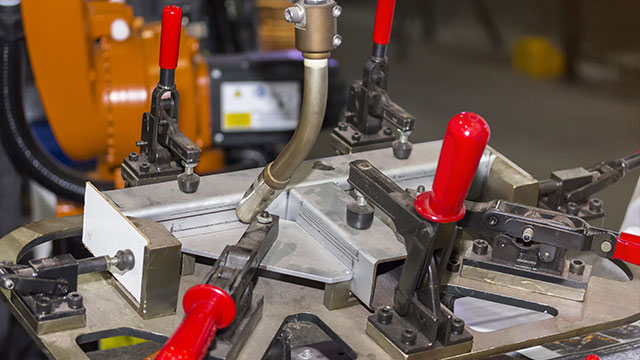

The process of designing jigs and fixtures entails the development of specialized equipment that aids in securing and aligning components throughout manufacturing processes like milling, drilling, and welding.

Jigs act as guides for cutting tools, while fixtures serve the purpose of firmly holding the workpiece in position. These tools are customized to suit particular parts and procedures, with the aim of boosting precision, reducing setup time, and enhancing efficiency.

Our skilled team of engineers and designers work closely with clients to understand their unique needs and create customized solutions that enhance operations and minimize costs. By utilizing advanced 3D modeling software, we efficiently create prototypes for testing and evaluation before final production.

Jig & Fixture Design Capabilities

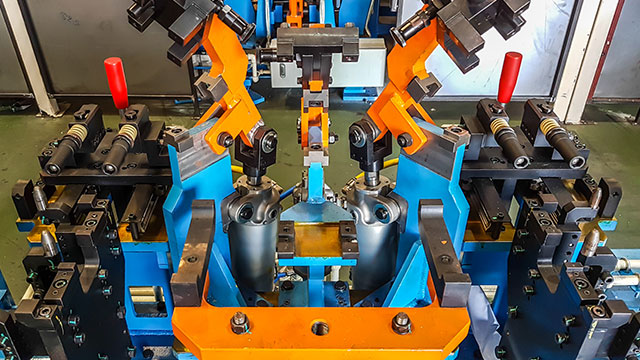

Body in White Manufacturing Tool & Fixture Design

In the automotive manufacturing process, Body in White (BIW) refers to the stage where sheet metal components of the vehicle are welded together. The use of jigs and fixtures ensures the appropriate alignment of all components. After the BIW manufacturing process is completed, major components like the engine, chassis, and trim can be installed, and the vehicle can be painted.

With an emphasis on increasing productivity and efficiency, PMC is an experienced provider of tool and fixture designs for the automotive industry. Our team, comprised of accomplished engineers and designers, innately understand the significance of precision and efficiency during the BIW manufacturing process, and endeavors to provide solutions that will optimize your operations.

Welding Fixture Design

Welding fixture design improves efficiency, quality, and safety while reducing costs and providing consistency in the welding process. It helps to ensure accurate and consistent welds, reduces the risk of accidents and injuries, and saves time and money in material waste and labor costs.

Rely on our team's profound understanding of welding procedures and the distinct demands of diverse sectors. We collaborate closely with our clients to develop welding fixtures that fulfill particular requirements and detect problems in the design phase at an early stage.

General Assembly Tool & Fixture Design

General Assembly Tool & Fixture Design can significantly enhance the precision, speed, and consistency of assembly processes, resulting in higher quality products and increased productivity. By providing a secure and stable platform for the assembly of parts, tool and fixture design can also improve worker safety and reduce the risk of errors or defects.

Utilizing state-of-the-art rendering software, our skilled teams possess the ability to customize tools and fixtures that align with your specific needs and prerequisites.

PMC Design Benefits

- Customized design: We design tailor-made jigs and fixtures to cater to specific requirements of a manufacturing process or product.

- Change Management Design Support: PMC provides comprehensive design support, including change notice support, modifications, engineering changes, drawing changes, and CAD level modifications. We also offer support for Bill of Materials and layout pneumatic drawings.

- Safety compliance: PMC designs jigs and fixtures that conform to safety regulations and standards to minimize the risk of injuries during manufacturing.

- ISO 9001-2015(QMS) & ISMS 27001-2013 Certified: ISO certification ensures that the design and construction of jigs and fixtures comply with international quality standards, providing assurance to customers that they are manufactured using a consistent and reliable process.

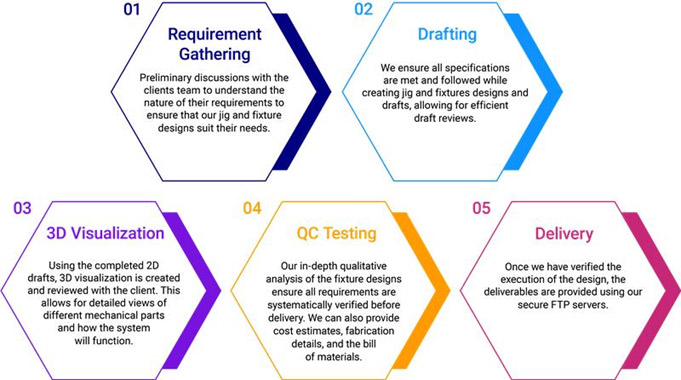

Our Jig & Fixture Design Process

01. Requirement Gathering

We hold a preliminary discussion with your team to understand the nature of your requirements, enabling us to design jigs and fixtures that are tailored to your specific requirements.

02. Drafting

During this stage we gather data and specifications to create a preliminary 2D design, ensuring your requirements are satisfied.

03. 3D Visualization

After the 2D drafts are complete, we generate a 3D visualization to enable clients to examine various mechanical parts and to test the interaction with other components.

04. QC Testing

To ensure compliance with all requirements, we conduct a comprehensive qualitative analysis of the jig and fixture designs. Additionally, if necessary, we can develop cost estimates, fabrication details, and a bill of materials.

05. Delivery

Upon internal approval, we use our secure FTP servers to deliver the final product.

Software & Technologies

PMC has in-depth experience with a variety of common software options that are used in tool and fixture design. Software utilization will vary on specific client needs, industry preference, and the company preference.

Jig & Fixture Hardware Production

PMC has extensive experience in the design and construction of jigs and fixtures. We offer design services for these essential tools that help improve manufacturing efficiency and ensure quality standards. In addition to our design capabilities, PMC also facilitates jig and fixture builds. We work closely with clients to understand their unique requirements and then oversee the fabrication and assembly of the jigs and fixtures to ensure they meet the required specifications. This end-to-end approach ensures clients receive a complete solution for their jig and fixture needs.

Jig & Fixture Market Areas

The advantages of jig and fixture design are widespread across various industries, as it facilitates the efficient and precise assembly of components, resulting in enhanced productivity and lower costs.

It also enables the optimization of production space and compliance with safety regulations and standards, which ultimately culminates in a superior final product. It is vital to have experienced tool and fixture specialists, like those on staff at PMC, who play a critical role in the manufacturing process.

- Automotive Jig & Fixtures

- Aerospace Jig & Fixtures

- Industrial Machinery Jig & Fixtures

- Medical Devices Jig & Fixtures

- Consumer Product Jig & Fixtures

Why Choose PMC: Our Experts

Our tool and fixture design services offer:

- Competitive pricing as a cost-effective and quality solution provider for our clients

- A rigorous quality assurance process to guarantee that the final product satisfies all of our clients' requirements and specifications.

- Extensive experience and knowledge from our engineers and designers with 30+ years in the manufacturing industry

- Deep industry knowledge and a large talent pool gives you confidence in customized design solutions that increase efficiency and reduce costs

- Strict compliance with regional safety regulations and standards to ensure a safe manufacturing process

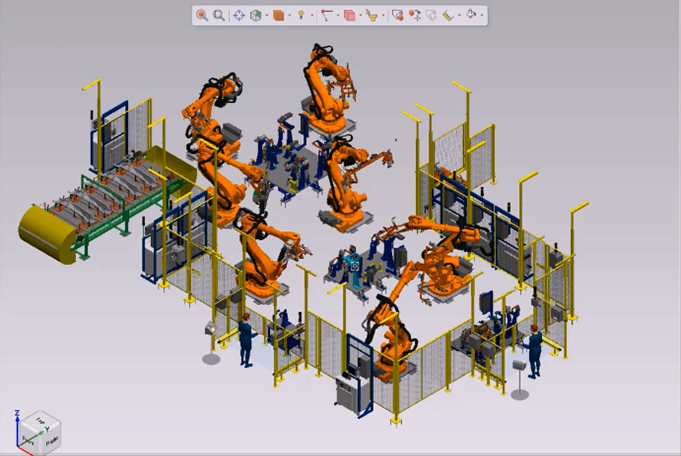

Related Service: Robotics Simulation Consulting

Our services aid in the design, testing, and optimization of robotic systems using computer simulation. By leveraging simulations, our clients can detect and address potential problems with their robotic systems before they are physically built, saving them valuable time and resources. Moreover, our simulations can replicate jigs & fixtures, end effectors, and human interaction to enhance the efficiency of robotic systems.

Frequently Asked Questions for Jigs & Fixtures

Speak with one of our Jig & Fixture Design Experts!

Send a message to our team by filling out the form below. Describe your project, ask questions, or even request a bid.

An expert from our team will be in touch with you within one business day!