Overview

SIMUL8 provides excellent ease of learning and use, enabling client industrial engineers to rapidly achieve a high degree of self-sufficiency in model building. Additionally, the software includes a powerful yet conceptually simple language –Visual Logic– which permits the modeler to customize process logic. Sixteen standard distributions (e.g. normal, triangular, uniform, exponential, Erlang, lognormal, and Weibull) are provided with the software, and the user can readily define customized empirical distributions.

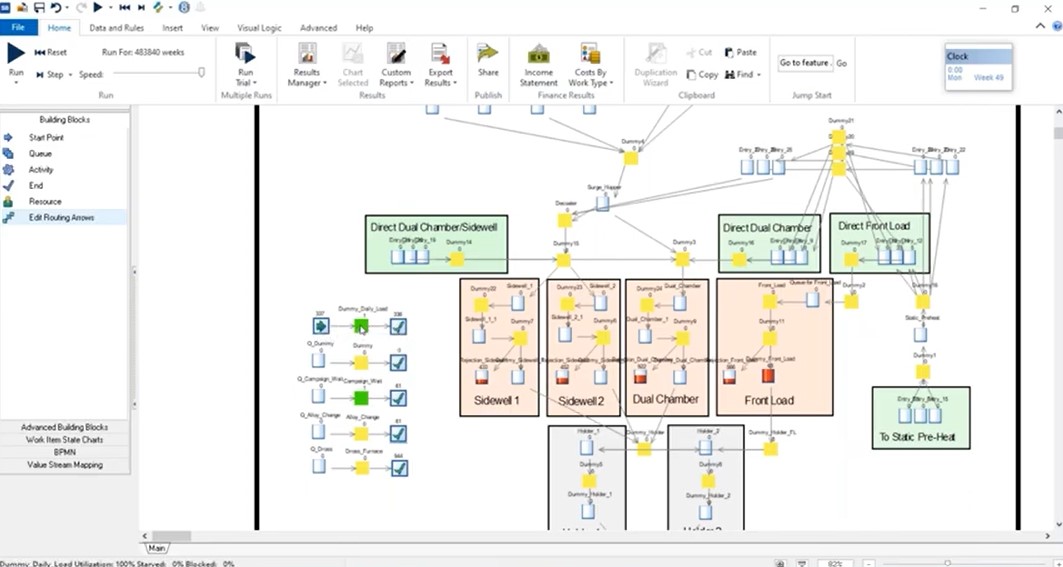

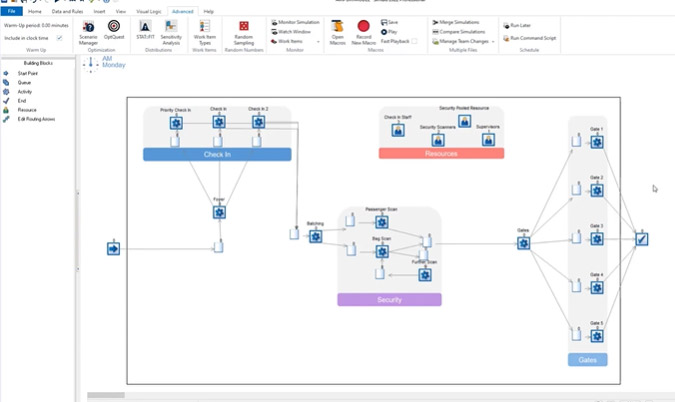

SIMUL8 enables concurrent building of simulation models and their animation using the basic elements of Start Point, Queue, Activity, End, Resource, Conveyor, Loader, and Vehicle. SIMUL8 supports user creation and use of customized, reusable libraries of simulation components.

PMC provides consulting, installation, training, implementation, and support services for SIMUL8. Contact Us today for more information or to request a quote.

SIMUL8 models

SIMUL8 can be used to model any process where there is a flow of work. Main areas of use are manufacturing, health care, contact centers and supply chain. Applications include:

- Manufacturing systems – such as assembly line models and job shops.

- Logistic systems – involving transfer of work or inventory among work areas and buffers.

- Administrative systems – such as those in health care record-keeping or probation/parole offices.

- Client-service systems – such as banks, hotel registration, airports, and retail.

Inputs and Outputs

These are the most common parameters of a SIMUL8 model, which are set by the user to influence the conditions of a simulated environment:

- Cycle times

- Production rate

- Buffer Capacity

- Arrival rates

- Downtime frequency and duration

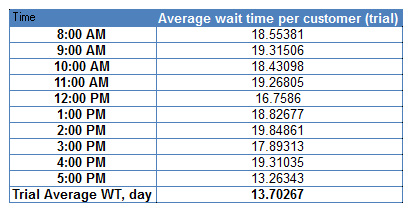

Outputs valuable in supporting engineering and management decisions include:

- Equipment utilization

- Bottleneck identification

- System throughput

- Inventory levels

- Queue lengths and wait times

Contact Us

Please write your questions in the following form and we will get to you as soon as possible. We look forward to helping you achieve your goals.

GET TO KNOW MORE OF OUR SERVICES

Simulation Modeling and Analysis

Simulation modeling is the process of creating and analyzing a digital prototype or virtual representation of a physical model or a system to predict its performance in the real world. Simulation modeling allows proposed changes to be tested, and productivity impact analysis of these changes to be performed.