Unlock Innovation and Efficiency in Manufacturing with High-Precision 3D Scanning Services

With precise measurement, analysis, and visualization capabilities, our scanning services enable enhanced efficiency and innovation throughout your manufacturing process. By integrating Manufacturing 3D scanning services with BIM to FM, you can benefit from real-time monitoring, preventive maintenance, optimized space utilization, and energy management.

3D Laser scanning coupled with three-dimensional digital twin modeling, provides a high return on investment and powerful solution for reducing construction and operational costs.

Why Choose PMC

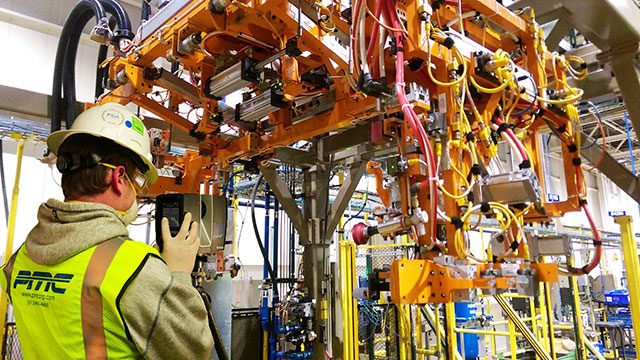

We scan large scope areas. Manufacturing and Industrial Plants pose unique challenges when it comes to scanning. Expansive areas, often spanning hundreds of thousands or even millions of square feet, necessitate a distinct scanning approach. Having scanned hundreds of millions of square feet, PMC has the skills needed to provide quality results.

We work with your schedule. Many facilities operate around the clock and have limited downtime, causing the identification of suitable scanning windows to present a challenge. PMC works with each schedule to effectively accomplish tasks that require innovative problem-solving.

We support Rapid Change. As manufacturing and industrial plants embrace Industry 4.0 advancements, the rapid pace of change poses considerable challenges. PMC offers innovative solutions that enable scanning to be effectively conducted in dynamic and rapidly evolving environments.

Cost Effectiveness: PMC's laser scanning technology eliminates manual measurements and reduces site visits, saving time, travel expenses, and minimizing the risk of rework. Our cost-effective approach delivers accurate data capture and virtual inspections, leading to savings in materials, labor, and project delays.

Safety is our priority. We possess the expertise and caution needed for Manufacturing and Industrial Plants. Our team follows a comprehensive Safety Policy and undergo specialized training specifically tailored to the industrial setting.

Our Industry Experience Includes:

Automotive

Appliance Manufacturing

Building Materials

Chemical Plants

Food and Beverage

Manufacturing Equipment

Oil & Gas

Paper Mills

Pharmaceutical

Power Distribution

Steam Plants

Steel Mills

3D Scanning Benefits for Manufacturing

- Deliver cost-effective and timely results, meeting your project deadlines.

- Achieve an overall reduction in operational costs reduce project timelines.

- Ensure accurate measurements and documentation, minimizing errors and discrepancies.

- Facilitate better visualization, analysis, and understanding of the scanned environment, supporting informed decision-making.

- Reduce the need for humans to enter hazardous or dangerous environments.

- Enable the detailed documentation and preservation of historical sites, cultural heritage, and important assets.

- Promote better communication and collaboration among project stakeholders and provide a shared understanding and alignment of project goals.

3D Scanning Features for Manufacturing

- Capture detailed 360-degree color panoramic images for comprehensive documentation purposes.

- Advanced processing techniques to generate comprehensive deliverables.

- Rigorous quality control measures to ensure accuracy and reliability.

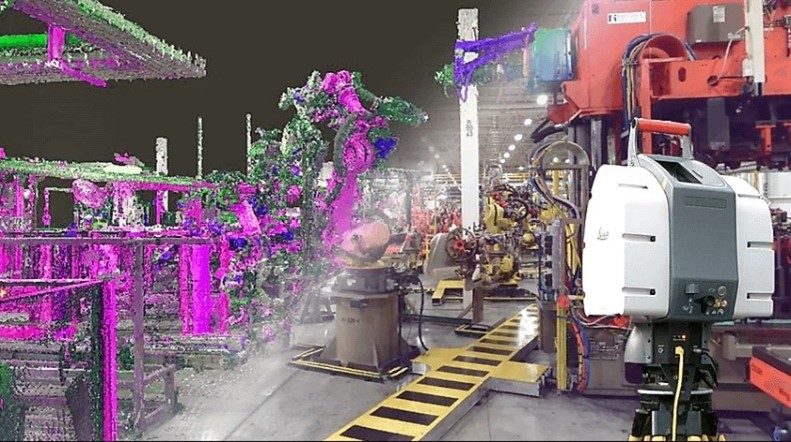

- Acquire detailed and precise laser scan point cloud data with survey-grade accuracy.

- Minimize costs associated with frequent site visits due to incomplete measurements.

- Streamline the scanning and conversion process for multiple areas with high efficiency.

- Alleviate workload overflow to ensure on-time delivery.

- Benefit from round-the-clock support and assistance.

- Effectively manage and organize data for improved efficiency and accessibility with streamlined documentation and archiving.

Related Service: Building 3D Scanning

We use advanced building scanning technology to create precise digital models of buildings and structures. With utilization of laser scanning, we capture the point-cloud data and convert into CAD models including extremely accurate measurements. We capture their physical attributes and details, to highly benefit architectural design, renovation planning, facility management, and historical preservation.

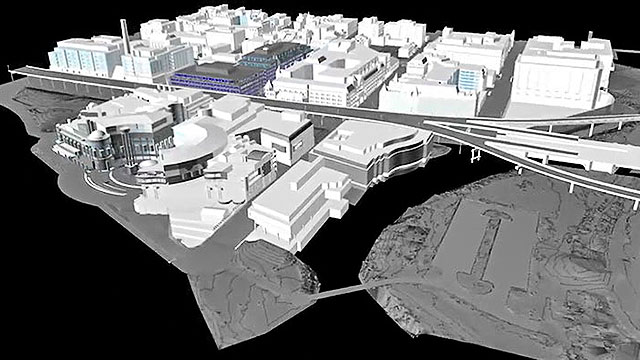

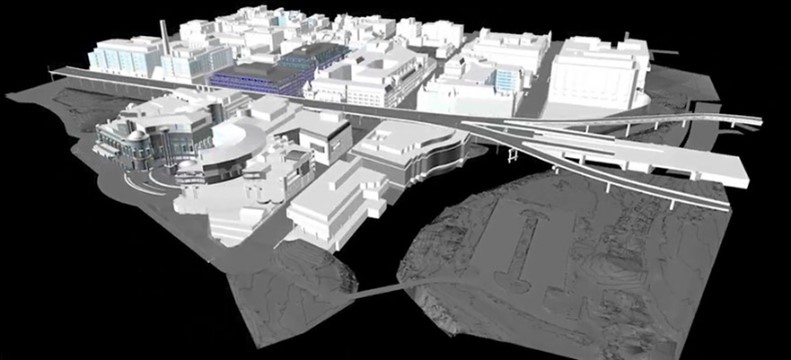

Related Service: Digital Twin in Reality Capture

PMC specializes in reality capture techniques such as laser scanning, drones, and photogrammetry, to gather precise digital data points and construct intricate three-dimensional models of structures, equipment, and even entire communities. Our process allows us to deliver authentic digital twins to our clients. With our state-of-the-art software and customized solutions, we facilitate precise predictive maintenance, intricate theoretical models, efficient manufacturing changeovers, and effective urban development and planning.

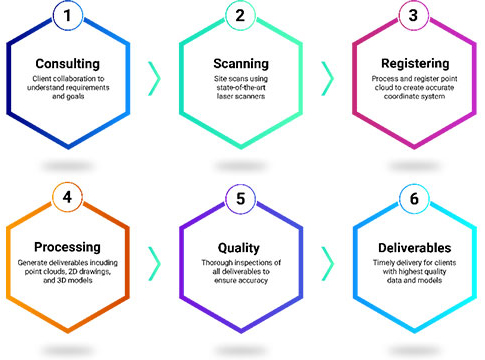

Our Laser Scanning Process

Consulting: Through close collaboration, we work closely with our clients to gain a deep understanding of their project requirements and goals

Scanning: PMC employs state-of-the-art laser scanners to perform site scans, capturing precise and detailed data.

Registering: Our skilled engineers meticulously process and register the point cloud, establishing an accurate coordinate system for precise measurements.

Processing: We generate comprehensive deliverables, including point clouds, 2D drawings, and 3D models, utilizing advanced processing techniques.

Quality Control: With rigorous quality control measures, we conduct thorough inspections of all deliverables to ensure the utmost accuracy and reliability.

Timely Delivery: Our dedicated team prioritizes timely delivery, providing clients with the highest quality data and models, meeting their project needs effectively

Software & Technologies

FARO Laser Scanners

NavVis Mobile Scanners

AutoDesk Suite

Revit BIM Software

FARO Terrestrial LiDAR

NavVis Wearable Mobile Scanning

Mobile LiDAR

Professional Drone & sUAS

Our Experts

Having successfully completed hundreds of projects and conducted over 50,000 site scans, PMC possesses a deep understanding of the unique challenges and requirements of the manufacturing sector. We are able to capture accurate and detailed 3D representations of objects and environments, using the latest scanning technology to complete 1,000,000 square feet (about the area of Chicago's Millennium Park) or more in just a week. Whether you have one site or a network of 10,000 sites, we have the expertise to efficiently capture, model, and manage your library of digital twins.

PROJECTS

CASE STUDIES

Frequently Asked Questions for 3d Building Laser Scanning Services

Let's talk about how we can help with your next project!

Send a message to our team by filling out the form below. Describe your project, ask questions, or even request a bid.

An expert from our team will be in touch with you within one business day!