Simulation Of Medical Laboratory Operations To Achieve Optimal Resource Allocation

SIMULATION OF MEDICAL LABORATORY OPERATIONS TO ACHIEVE OPTIMAL RESOURCE ALLOCATION

Ravindra Lote | Edward J. Williams | Onur M. Ülgen

PMC

15726 Michigan Avenue Dearborn, MI 48126 U.S.A.

ABSTRACT

As competitive pressures increase within the health care sectors of economies worldwide, and especially within the United States, the importance of achieving operational efficiencies to reduce costs and thence to increase profits while keeping and attracting customers steadily increases. Simulation, optimization, time studies, value stream mapping, and process improvement methodologies have long been key allies of the industrial engineer assigned to find and progress along the often difficult and challenging road leading to such efficiencies; experienced industrial engineers know these methodologies work better synergistically than individually. The presentation here, and undertaken collaboratively between the medical laboratory (client) and the industrial engineering service company (consultant), concentrates primarily on the use and achievements of discrete-event process simulation and its allied industrial-engineering techniques in improving the operations of a medical testing laboratory, and hence its services to its clients, both hospitals and clinics.

INTRODUCTION

Historically, the first major application area of discrete-event process simulation was the manufacturing sector of the economy (Miller and Pegden 2000). With the passage of time, simulation has become more closely allied with other industrial engineering techniques such as time and motion studies, value stream mapping, ergonomics studies, and “5S” examinations used concurrently to improve generic operations (Groover 2007), and has also expanded rapidly into the service and health care industries (Lowery 1998). Illustrative examples of simulation applications to the health care sector appearing in the literature are: improvement of appointment scheduling in a dental clinic (Czech, Witkowski, and Williams 2007), the analysis of incentives and scheduling within the operating room of a major metropolitan hospital (Ferrin et al. 2004), the coordinated provision of emergency medical services immediately subsequent to a serious traffic accident (Guimarans et al. 2006), and aggressive efforts to improve health care delivery in hospitals in the United Kingdom (Pidd and Günal 2008). The survey article (McGuire 1998) provides an excellent overview of simulation use in health care.

Improvement of the delivery of health care services is especially pressing in the United States. As Margaret Brandeau bluntly stated in her keynote address to the 2008 Winter Simulation Conference (Miami, Florida, United States, 8 December 2008) “The United States spends more per capita on health than any other nation, yet has worse health outcomes than many other countries. Moreover, expenditures on health in the U.S. are growing rapidly, and are taking up an increasingly larger share of per capita gross domestic product.” (Brandeau 2008). These urgently needed improvements involve the metrics of timeliness, quality, and cost – and these metrics are strongly affected by services the typical patient does not “see” (Galloro, 2008) – such as those provided by medical laboratories. The recent work of (Chinea, Rodríguez, and González 2009) provides an excellent synopsis of simulation used in hospital resource management.

In the case study discussed here, a medical laboratory in the eastern part of the United States, sought to improve its financial efficiency, operational efficiency, and service to its clients. Accordingly, this laboratory undertook to use, with the collaboration and guidance of an industrial engineering consulting company, the techniques of industrial engineering, including discrete-event process simulation. This certified and accredited laboratory provides, over a multi-county area, pick-up and delivery courier services for supply requests, medical specimens, test result reports, and medical supplies. In this context, the project goals of the client laboratory were to:

- Optimize the numerous courier routes to improve transport efficiency, particularly to deliver work (i.e., medical specimens to be analyzed) to the laboratory earlier in the work day. In the specific context of this simulation project, an ongoing, formally stated objective was (and is) “test impact of route optimization initiative on load leveling of resources and provide necessary feedback for further fine tuning of optimization model.” Hence very early in the life of this project, the client recognized the first phase of the simulation study as a “bootstrap” toward continuous improvement (usually this recognition dawns later, after a client – especially one new to simulation – comes to appreciate the analytical power of simulation).

- Gain analytical insights into the interrelationships between courier route improvements and operational performance metrics of the laboratory

- Achieve leveling of workload, in conjunction with leveling of resource usage, within various departments (e.g., serology, microbiology, and hematology) departments in the laboratory via smoother delivery of

- Achieve cost-savings via appropriate redeployment of personnel with no degradation of service metrics to hospitals and clinics (the clients of the laboratory).

OVERVIEW OF PROCEDURES AT THE MEDICAL LABORATORY

The operations studied intensively and comprehensively at this laboratory comprised the delivery of medical specimens to the laboratory, their processing within the laboratory, pick-up and delivery of items entrusted to its courier service, and delivery of test result reports and medical supplies to its client hospitals and health care clinics. At the initiation of the project, the laboratory used a fleet of fifteen courier vehicles, employed fifteen full-time-equivalent headcount, and ran eleven total courier routes daily (only one of these a local run). Originally, courier routing instructions were handwritten on route sheets. Also, the laboratory was acutely aware of chronically high specimen processing costs, due primarily to overtime attributed to unbalanced rates of specimen arrival. The arrival rates predictably spiked about 11:30 each morning, between 14:00 and 17:00 each afternoon, and again at 22:00 each evening. The number of requisitions processed was typically between 1,000 and 1,100 per day. Unbalanced rates of specimen arrival resulted in suboptimal utilization of medical technologists. Overtimes were frequently enforced, in addition to the implementation of a midnight shift, to achieve required turn-around-time of 24 hours. Early observations and discussions with the client attributed this undesirable situation to suboptimal workload leveling. Additionally, unobtrusive workload observation techniques confirmed a long-standing client suspicion that between ½ and ¾ hour of courier time was typically squandered between specimen drop-off and route continuation. As so often happens (Kroemer and Grandjean 1999), stressful working conditions, including compulsory overtime, often resulted in erroneous specimen results. Accordingly, the client and the consultant decided to concentrate early efforts on improvement of the courier routings and assignment of personnel thereto, not operations within the testing laboratory itself.

DATA COLLECTION AND INPUT ANALYSIS

A major portion of the data collection involved the courier routes; actual trip times (which had high variability) were collected and analyzed for each route. This need for extensive, accurate data collection is frequent in simulation studies, especially those pertaining to the health care industry. As (Carter and Blake 2004) remark, “In our experience in health care, no one ever had the right data in the form that we needed it.” In this study, data collection included not only the routing details mentioned above, but the resource availabilities of couriers by shift, the proportions of specimens requiring attention in the chemistry, hematology, microbiology, and serology subdivisions of the laboratory, and staffing levels in each of these divisions. Additionally, all incoming specimens required generic preprocessing before being routed to one or more of the laboratory subdivisions; input data were also collected to assess the workload imposed by this preprocessing.

CONSTRUCTION, VERIFICATION, AND VALIDATION OF THE SIMULATION MODEL

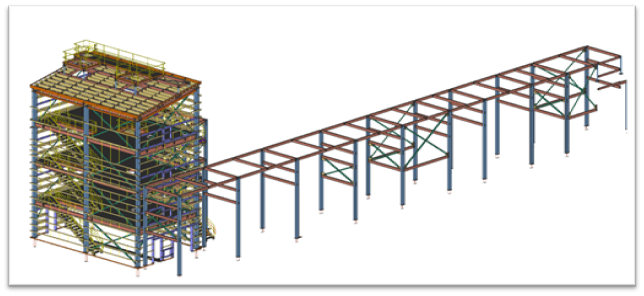

Construction of the simulation model began concurrently with the collection and statistical analysis of its input data. The simulation software tool chosen in consensus by the client and the industrial engineering company was Enterprise Dynamics® (Hullinger 1999). This software tool, a worthy competitor among many, provides comprehensive analysis techniques, a convenient user interface, excellent three-dimensional animation, and provision for modelers to construct customized reusable “atoms” (Swain 2007). For the convenience of both the modelers and the client’s management, the simulation model was constructed to read its input data from Excel® workbooks and to export its numerical results to Excel® workbooks.

The scope of the simulation model included the courier team’s acquisition of specimens, their preprocessing on delivery to the laboratory, their subsequent routing to specialized analytical operations (chemistry, hematology, microbiology, and serology), and the delivery of results and any requisitioned medical supplies to the client hospital or clinic. In the model, all courier routes were “black-boxed,” i.e., treated as an advance of time sampled from the distribution of actual trip times collected for each pertinent route. Additionally, and with client concurrence, weekends were not modeled, and operator walk times and lunch breaks were ignored.

Verification and validation of the simulation model used many techniques well recognized in the literature (Sargent 2004), such as:

- Running the model with only one

- Running the model with only one courier

- Eliminating all randomness and then cross- checking results against “desk ”

- Using structured walkthroughs of model logic and

- Undertaking “directional testing” (e.g., if a cycle time increases, throughput should decrease or remain the same).

- Cross-checking extensively with the client, including step-by-step tracking of model execution and its animation.

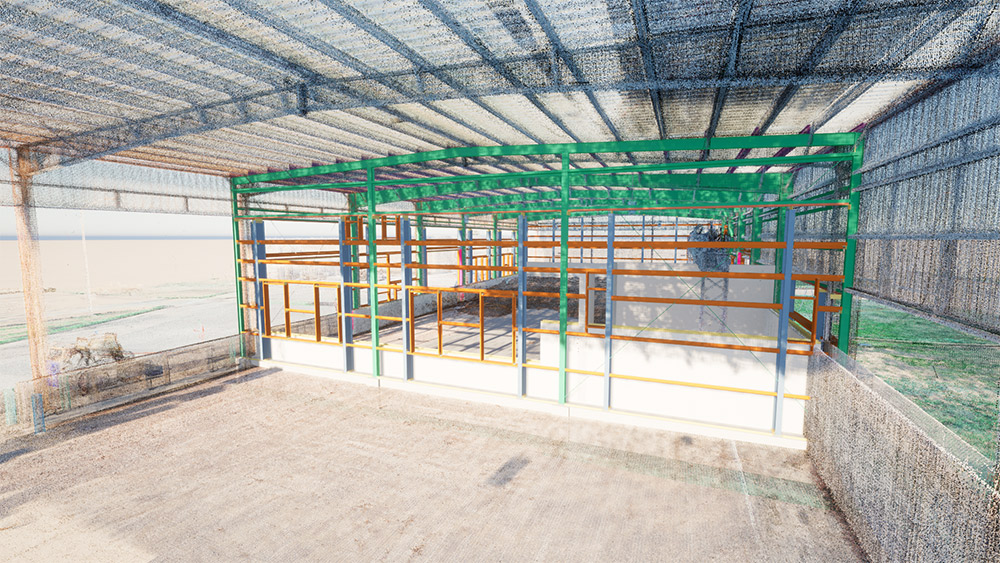

Availability of three-dimensional animation proved of ongoing value when the results were presented to client engineers and those engineers in turn presented them to their upper management (Kelton, Sadowski, and Sturrock 2007). An example of a three-dimensional animation appears as Figure 3 in the Appendix. Likewise, the availability of interactive route maps interfaced with the simulation analysis, one of which appears in Figure 4, were a valuable visual aid to understanding the implications of various suggestions for routing improvement.

RESULTS AND OPERATIONAL CONCLUSIONS

The results of this simulation study included several pertinent and valuable recommendations, among them:

- Optimizing routes initially in use allowed the re- allocation of two couriers.

- One re-allocated courier, redeployed as a runner, retrieved specimens from other couriers returning to the

- Workload leveling achieved as a result of optimizing the routes helped the client eliminate the night shift and improve utilizations of medical technologists during the morning One example of workload leveling achieved is illustrated in Figures 1 and 2, which show the percent utilizations of the medical technologists in the chemistry department. Resource leveling improved from “considerably worse than two-to- one” to “uniformity of usage within 10%.” Similar quantitative improvements were achieved in the serology, microbiology, and hematology departments.

A lesser ratio improvement, but one involving a more heavily utilized group of technologists overall (and hence of high importance to the client) was achieved in the preprocessing department, as shown in Figures 5 and 6 in the Appendix. In this department, maximum utilization fell from 100% (and that among half of the technicians) to 97%, and minimum utilization rose from 60.2% to 81.7%.

- Route optimization and subsequent workload leveling saved approximately $110,000 annually in payroll

It is important to understand that the progress from optimization of courier routes to achievement of workload leveling was not a quick “step one, step two” process. The actual work involved improving the courier routes, testing the impact of these improved routes on workload leveling, using insights from the newly improved leveling to further improve the routes, etc. – an iterative process. Relative to the simulation experimentation itself, the scenario runs were terminating (due to the daily “restart” nature of the courier runs and laboratory operations), each replication lasted six weeks of simulated time, and sufficiently narrow confidence intervals required four replications of each scenario examined.

Attractively, no personnel represented by the payroll cost savings were laid off; rather, the client company deployed them in expansions of this service and in newly offered services, thereby increasing its profitability. As one example of this reallocation, one courier was newly deployed as a runner assigned to retrieve laboratory specimens, together with handheld computers already in routine use to upload preliminary computations to desktop computers, from other couriers returning to the central laboratory from their runs.

INDICATED FURTHER WORK

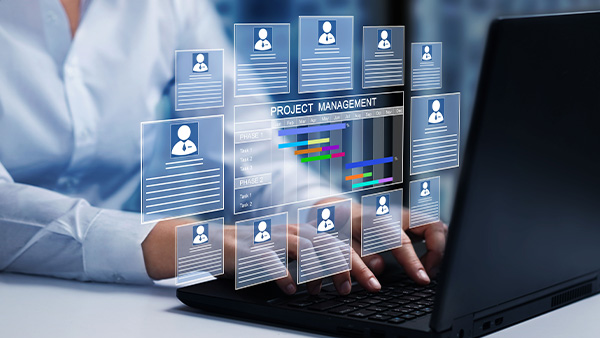

As a matter of standard policy, the model was built and documented with the intention that it be available for and adaptable to continued use. Such continued use is indeed already impending: almost inevitably, changes in the number and location of customer pick-up/drop-off points are appearing, as are changes in the “specimen traffic” (number of specimens arriving or departing at each of these points). Therefore, courier routing optimization will be an ongoing process. Via the Excel® input interface, client analysts and managers can and do run the model to incorporate these changes, the routing optimization is successfully keeping apace of the market demand changes experienced by the laboratory.

Additionally, as a result of a first successful foray into simulation by the client company, its management is now considering the use of simulation for an incremental study focusing attention more specifically on the “in-house” laboratory operations.

OVERALL CONCLUSIONS AND IMPLICATIONS

This case study illustrates the value of simulation in a setting fundamentally logistical, in the context of providing health care. Use of simulation in conjunction with allied analytical techniques such as route optimization, value stream mapping, work sampling, and resource leveling provides synergistic value to all these industrial engineering techniques. Whereas many studies documented in the literature are directed to the “front of the house” delivery of care directly visible to patients, this analysis devoted attention to a “back of the house” function, much less conspicuous from a patient’s viewpoint, but nonetheless vital to the delivery of timely and high-quality health care at manageable cost.

ACKNOWLEDGMENTS

The authors gratefully acknowledge the contributions of Mike Ricard, Kevin Kohls, and Eric Lammers, industrial engineers and colleagues, to this project. Additionally, various anonymous referees have contributed valuable suggestions to improve the presentation and organization of this paper.

REFERENCES

Braudeau, Margaret. 2008. Modeling and Simulation in Public Health: A Little Help Can Go a Long Way. In Proceedings of the 2008 Winter Simulation Conference [ISBN 978-1-4244-2708-6, IEEE catalog number CFP08WSC-CDR, Library of Congress 87-654182], eds. Scott Mason, Ray Hill, Lars Mönch, Oliver Rose, Tom Jefferson, and J. W. Fowler.

Carson II, John S. 2004. Introduction to Modeling and Simulation. In Proceedings of the 2004 Winter Simulation Conference, Volume 1, eds. Ricki G. Ingalls, Manuel D. Rossetti, Jeffrey S. Smith, and Brett A. Peters, 9-16.

Carter, Michael W., and John T. Blake. 2004. Using Simulation in an Acute-Care Hospital: Easier Said than Done. In Operations Research and Health Care: A Handbook of Methods and Applications, eds. Margaret L. Brandeau, François Sainfort, and William P. Pierskalla,

191-215. Dordrecht, The Netherlands: Kluwer Academic Publishers.

Chinea, R. M. Aguilar, I. Castilla Rodríguez, and R. C. Muñoz González. 2009. Hospital Resource Management. In Simulation-Based Case Studies in Logistics: Education and Applied Research, eds. Yuri Merkuryev, Galina Merkuryeva, Miquel Àngel Piera, and Antoni Guasch. London, UK: Springer-Verlag London Limited, 65-84.

Czech, Matthew, Michael Witkowski, and Edward J. Williams. 2007. Simulation Improves Patient Flow and Productivity at a Dental Clinic. In Proceedings of the 21st European Conference on Modelling and Simulation, eds. Ivan Zelinka, Zuzana Oplatková, and Alessandra Orsoni, 25-29.

Ferrin, David M., Martin J. Miller, Sherry Winiger, and Michael S. Neuendorf. 2004. Analyzing Incentives and Scheduling in a Major Metropolitan Hospital Operataing Room through Simulation. In Proceedings of the 2004 Winter Simulation Conference, Volume 2, eds. Ricki G. Ingalls, Manuel D. Rossetti, Jeffrey S. Smith, and Brett A. Peters, 1975-1980.

Galloro, Vince. 2008. Healthcare Holds On Tight. Modern Healthcare 38(38):6-11 [22 September 2008].

Groover, Mikell P. 2007. Work Systems and the Methods, Measurement, and Management of Work. Upper Saddle River, New Jersey: Pearson Education, Incorporated.

Guimarans, D., J. J. Ramos, M. A. Piera, and A. Guasch. 2006. A Simulation Based Decision Tool to Coordinate Emergency Services in a Road Accident. In Proceedings of the 2006 Summer Computer Simulation Conference, eds. Agostino G. Bruzzone and Edward Williams, 110- 115.

Hullinger, D. Roger. 1999. Taylor Enterprise Dynamics. In Proceedings of the 1999 Winter Simulation Conference, Volume 1, eds. Phillip A. Farrington, Harriet Black Nembhard, David T. Sturrock, and Gerald W. Evans, 227-229.

Kelton, W. David, Randall P. Sadowski, and David T. Sturrock. 2007. Simulation with Arena, 4th edition. Boston, Massachusetts: The McGraw-Hill Companies, Incorporated.

Kroemer, K. H. E., and E. Grandjean. 1999. Fitting the Task to the Human, 5th edition. Philadelphia, Pennsylvania: Taylor and Francis Incorporated.

Lowery, Julie C. 1998. Getting Started in Simulation in Healthcare. In Proceedings of the 1998 Winter Simulation Conference, Volume 1, eds. D. J. Medeiros, Edward F. Watson, John S. Carson, and Mani S. Manivannan, 31-35.

McGuire, Frank. 1998. Simulation of Healthcare. In Handbook of Simulation: Principles, Methodology, Advances, Applications, and Practice, ed. Jerry Banks. New York, New York: John Wiley & Sons, Incorporated, 605-627.

Miller, Scott, and Dennis Pegden. 2000. Introduction to Manufacturing Simulation. In Proceedings of the 2000 Winter Simulation Conference, Volume 1, eds. Jeffrey A. Joines, Russell R. Barton, Keebom Kang, and Paul A. Fishwick, 63-66.

Mundel, Marvin E., and David L. Danner. 1994. Motion and Time Study: Improving Productivity, 7th edition. Englewood Cliffs, New Jersey: Prentice-Hall, Incorporated.

Pidd, Michael, and Murat Günal. 2008. Better British Hospitals: Improving Health Care with Whole Systems Thinking and Simulation. Industrial Engineer 40:12(24- 29) [December].

Sargent, Robert G. 2004. Validation and Verification of Simulation Models. In Proceedings of the 2004 Winter Simulation Conference, Volume 1, eds. Ricki G. Ingalls, Manuel D. Rossetti, Jeffrey S. Smith, and Brett A. Peters, 17-28.

Swain, James J. 2007. New Frontiers in Simulation: Biennial Survey of Discrete-Event Simulation Software Tools. OR/MS Today 34:5(32-43) [October].

AUTHOR BIOGRAPHIES

RAVI LOTE holds a bachelor’s degree in Mechanical Engineering (Shivaji University, India) and a master’s degree in Industrial Engineering (University of Massachusetts, Amherst). Currently, he is studying to earn a Masters in Business Administration from the Ross School of Business, University of Michigan in Ann Arbor, Michigan. He is a certified six sigma black belt (ASQ), a certified supply chain professional (APICS), and a certified MODAPTS practitioner. He is a Project Manager at PMC, and highly familiar with simulation and facilities-layout optimization systems including AutoMod®, WITNESS®, Simul8®, QUEST®, and Flow Planner®. He is a member of the APICS and American Society for Quality [ASQ].

RAVI LOTE holds a bachelor’s degree in Mechanical Engineering (Shivaji University, India) and a master’s degree in Industrial Engineering (University of Massachusetts, Amherst). Currently, he is studying to earn a Masters in Business Administration from the Ross School of Business, University of Michigan in Ann Arbor, Michigan. He is a certified six sigma black belt (ASQ), a certified supply chain professional (APICS), and a certified MODAPTS practitioner. He is a Project Manager at PMC, and highly familiar with simulation and facilities-layout optimization systems including AutoMod®, WITNESS®, Simul8®, QUEST®, and Flow Planner®. He is a member of the APICS and American Society for Quality [ASQ].

EDWARD J. WILLIAMS holds bachelor’s and master’s degrees in mathematics (Michigan State University, 1967; University of Wisconsin, 1968). From 1969 to 1971, he did statistical programming and analysis of biomedical data at Walter Reed Army Hospital, Washington, D.C. He joined Ford Motor Company in 1972, where he worked until retirement in December 2001 as a computer software analyst supporting statistical and simulation software. After retirement from Ford, he joined PMC, Dearborn, Michigan, as a senior simulation analyst. Also, since 1980, he has taught evening classes at the University of Michigan, including both undergraduate and graduate simulation classes using GPSS/HÔ, SLAM IIÔ, SIMANÔ, ProModelÒ, SIMUL8Ò, or Arena®. He is a member of the Institute of Industrial Engineers [IIE], the Society for Computer Simulation International [SCS], and the Michigan Simulation Users’ Group [MSUG]. He serves on the editorial board of the International Journal of Industrial Engineering – Applications and Practice. During the last several years, he has given invited plenary addresses on simulation and statistics at conferences or seminars in Monterrey, México; İstanbul, Turkey; Genova, Italy; Rīga, Latvia; Göteborg, Sweden; and Jyväskylä, Finland. He has served as Program Chair of the 2004, 2005, and 2006 Summer Computer Simulation Conferences, and also for the 2005 IIE Simulation Conference.

EDWARD J. WILLIAMS holds bachelor’s and master’s degrees in mathematics (Michigan State University, 1967; University of Wisconsin, 1968). From 1969 to 1971, he did statistical programming and analysis of biomedical data at Walter Reed Army Hospital, Washington, D.C. He joined Ford Motor Company in 1972, where he worked until retirement in December 2001 as a computer software analyst supporting statistical and simulation software. After retirement from Ford, he joined PMC, Dearborn, Michigan, as a senior simulation analyst. Also, since 1980, he has taught evening classes at the University of Michigan, including both undergraduate and graduate simulation classes using GPSS/HÔ, SLAM IIÔ, SIMANÔ, ProModelÒ, SIMUL8Ò, or Arena®. He is a member of the Institute of Industrial Engineers [IIE], the Society for Computer Simulation International [SCS], and the Michigan Simulation Users’ Group [MSUG]. He serves on the editorial board of the International Journal of Industrial Engineering – Applications and Practice. During the last several years, he has given invited plenary addresses on simulation and statistics at conferences or seminars in Monterrey, México; İstanbul, Turkey; Genova, Italy; Rīga, Latvia; Göteborg, Sweden; and Jyväskylä, Finland. He has served as Program Chair of the 2004, 2005, and 2006 Summer Computer Simulation Conferences, and also for the 2005 IIE Simulation Conference.

ONUR M. ÜLGEN is the president and founder of Production Modeling Corporation (PMC), a Dearborn, Michigan, based industrial engineering and software services company as well as a Professor of Industrial and Manufacturing Systems Engineering at the University of Michigan-Dearborn. He received his Ph.D. degree in Industrial Engineering from Texas Tech University in 1979. His present consulting and research interests include simulation and scheduling applications, applications of lean techniques in manufacturing and service industries, supply chain optimization, and product portfolio management. He has published or presented more that 100 papers in his consulting and research areas.

ONUR M. ÜLGEN is the president and founder of Production Modeling Corporation (PMC), a Dearborn, Michigan, based industrial engineering and software services company as well as a Professor of Industrial and Manufacturing Systems Engineering at the University of Michigan-Dearborn. He received his Ph.D. degree in Industrial Engineering from Texas Tech University in 1979. His present consulting and research interests include simulation and scheduling applications, applications of lean techniques in manufacturing and service industries, supply chain optimization, and product portfolio management. He has published or presented more that 100 papers in his consulting and research areas.

Under his leadership PMC has grown to be the largest independent productivity services company in North America in the use of industrial and operations engineering tools in an integrated fashion. PMC has successfully completed more than 3000 productivity improvement projects for different size companies including General Motors, Ford, DaimlerChrysler, Sara Lee, Johnson Controls, and Whirlpool. The scientific and professional societies of which he is a member include American Production and Inventory Control Society (APICS) and Institute of Industrial Engineers (IIE). He is also a founding member of the MSUG (Michigan Simulation User Group).

Your Partner in Productivity Improvement

Want to speak with one of our Industrial Engineering, Reality Caputre, or Simulation Experts? Contact us via the form below!

We look forward to helping you achieve your goals.

Recent posts