PMC Case Study | Warehouse Design and Staffing Simulation

PROJECT SUMMARY

PMC helped a major automaker design the layout of a parts warehouse. Using simulation, researchers determined the staffing levels that different proposed layouts needed to achieve the facility’s targeted throughput.

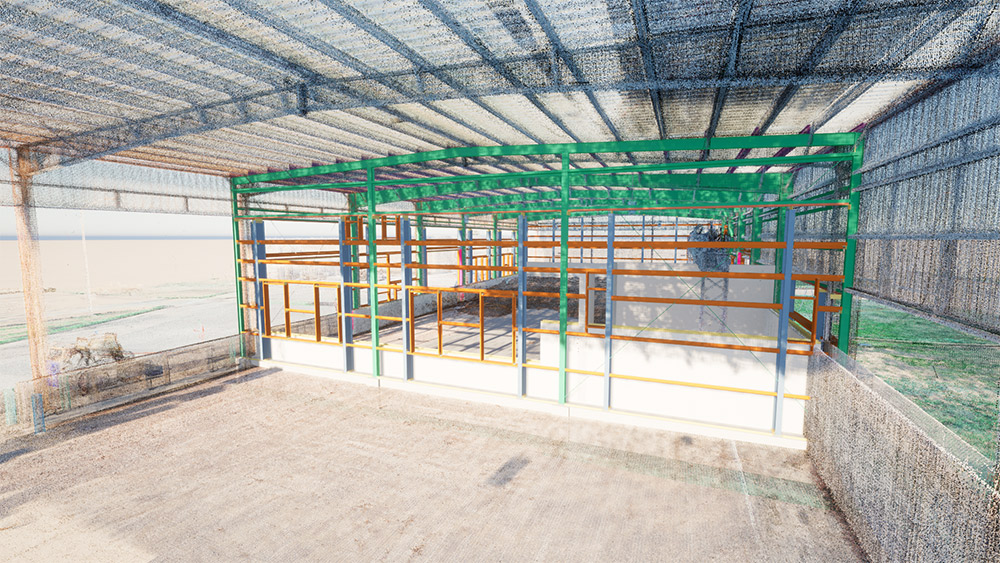

SYSTEM DESCRIPTION

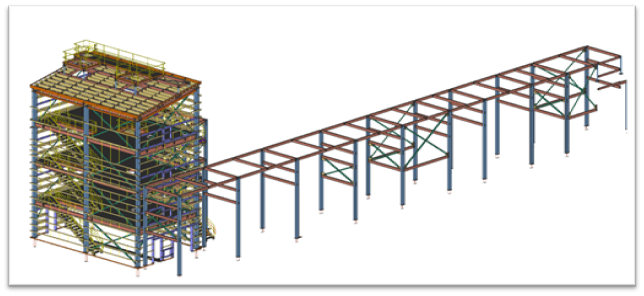

The proposed warehouse was to receive, store and distribute windshields and many parts associated with them. One group of resources, the “pickers,” were to traverse the warehouse picking parts out of inventory to fill purchase orders. Other resources, the “restockers,” were to continually replenish inventory. The physical layout of the plant was not yet determined; one proposal called for a two-tier system, with inventory arranged along seven aisles, while another prescribed a one-tier system and thirteen aisles.

OPPORTUNITY

Pickers and restockers were to work simultaneously, which raised issues of traffic flow, material flow and safety. Also, it was known that the warehouse would have to attain a high level of throughput, but the automaker wished to achieve this aim with a minimum of workers in order to limit labor costs. Given all these complications, the automaker needed to determine optimum warehouse configuration prior to construction, in order to prevent the future expense of high staff levels or overhaul of the physical layout.

APPROACH

The objective was to determine how many workers were required to safely and reliably produce a total throughput of 900,000 pieces per year for the one and two-tier proposed scenarios.

SOLUTION

Researchers began by collecting information on the specific dimensions of the proposed layouts. They also studied representative samples of parts orders, plans for storage of parts within the warehouse, and the decision algorithms and floor-scale motions that workers in the warehouse would need to make. After reviewing these findings with the client, PMC researchers built a series of simulation models.

BENEFIT

Results of simulation runs indicated that the one-tier scenario would yield the best performance, meeting the target of 900,000 pieces per year with only 13 pickers and 6 restockers.

Let our experts show you how our Services can support your projects!

Recent posts